E P I C | Plastic Pollution Emergency Response™

E P I C | Plastic Pollution Emergency Response™

FREQUENTLY ASKED QUESTIONS – PLASTIC TO FUEL MACHINE

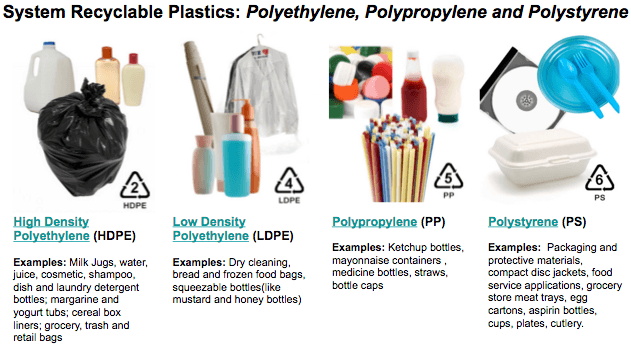

Q: What kind of plastics can be converted to oil?

A: Recyclable plastics include polypropylene (PP), polyethylene (PE) and polystyrene (PS), numbers 2, 4, 5 and 6.

Q: What kind of oil or fuel is converted from plastics?

A: Our system creates ASTM quality diesel and gasoline fuel. Approximately 75% of the output is diesel and the remainder is other oil.

Q: How much oil can the pyrolysis machine convert from one ton of plastic waste?

A: On average, one ton of plastic waste converts to 1000 liters of oil. (1 kg of plastic converts to 1 liter oil)

Q: What is the maximum output capacity?

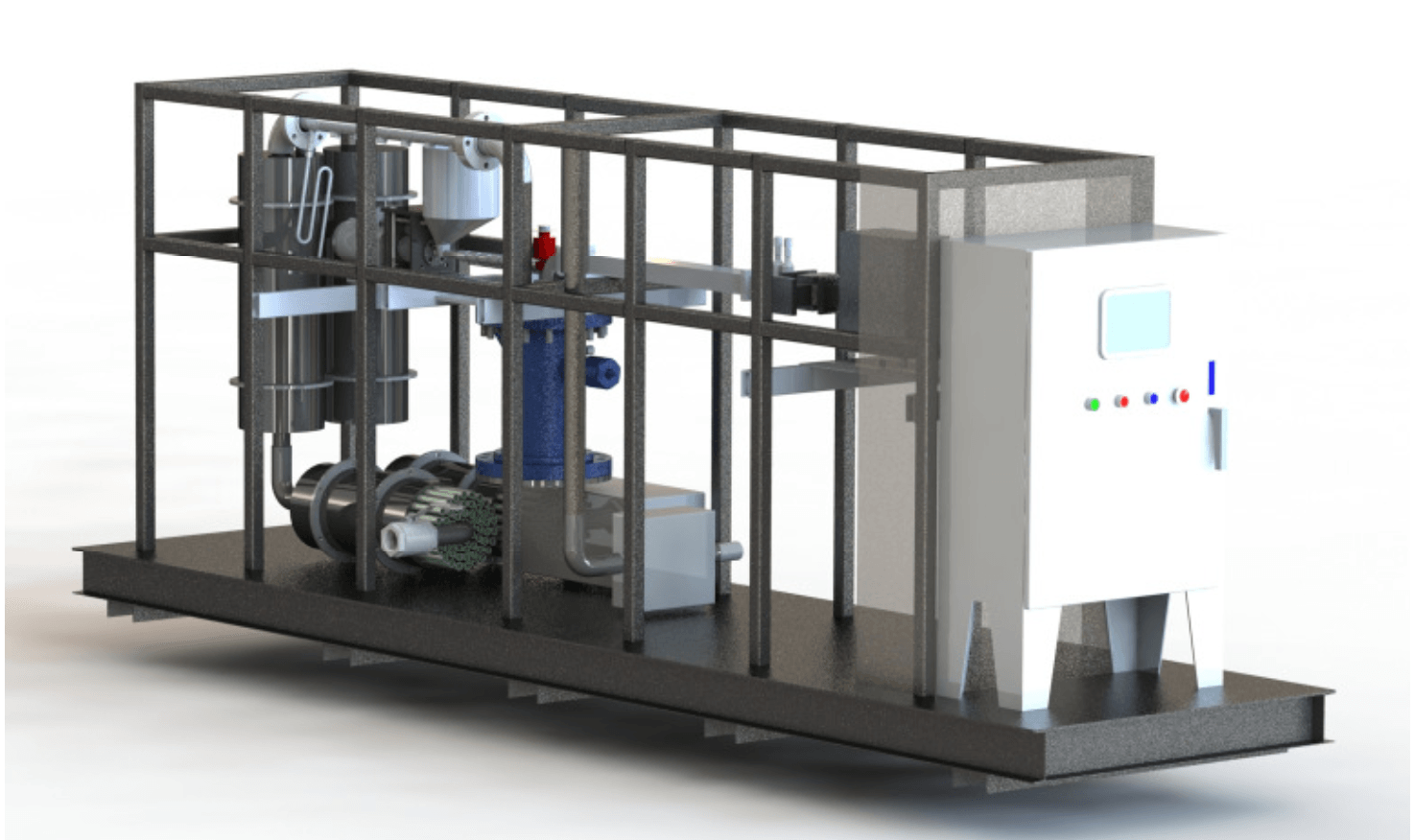

A: Resynergi offers a 5-10 ton input plastics per day unit.

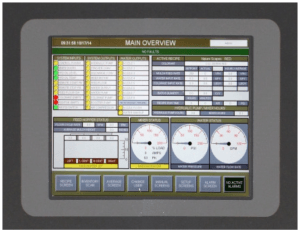

Pyrolysis Machine GUI interface

Q: What are the other outputs of the system?

A: Gases (primarily methane, ethane, propane and butane) as well as a small amount (< 5 %) of char (benign carbon) are produced. Off gases are mitigated by using a catalytic oxidizing system which breaks down the gases into a small amount of CO2 and H2O.

Q: What are the benefits of conversion technologies over incineration?

A: Incineration involves burning in the presence of air-oxygen. There is no burning involved in pyrolysis. Advanced thermal conversion technologies have several potential benefits over waste incineration, including lower environmental impacts, higher electrical conversion efficiencies, and greater compatibility with recycling. The volume of output gases as well as ash residual from a gasifier or a pyrolysis reactor is much smaller per ton of feedstock processed than from an incineration process. (THE SOUTHERN CALIFORNIA CONVERSION TECHNOLOGY PROJECT “Converting waste into renewable resources” www.SoCalConversion.org)